Salt & Straws Latest Ice Cream Flavors Were Made With Food Waste

Table Of Content

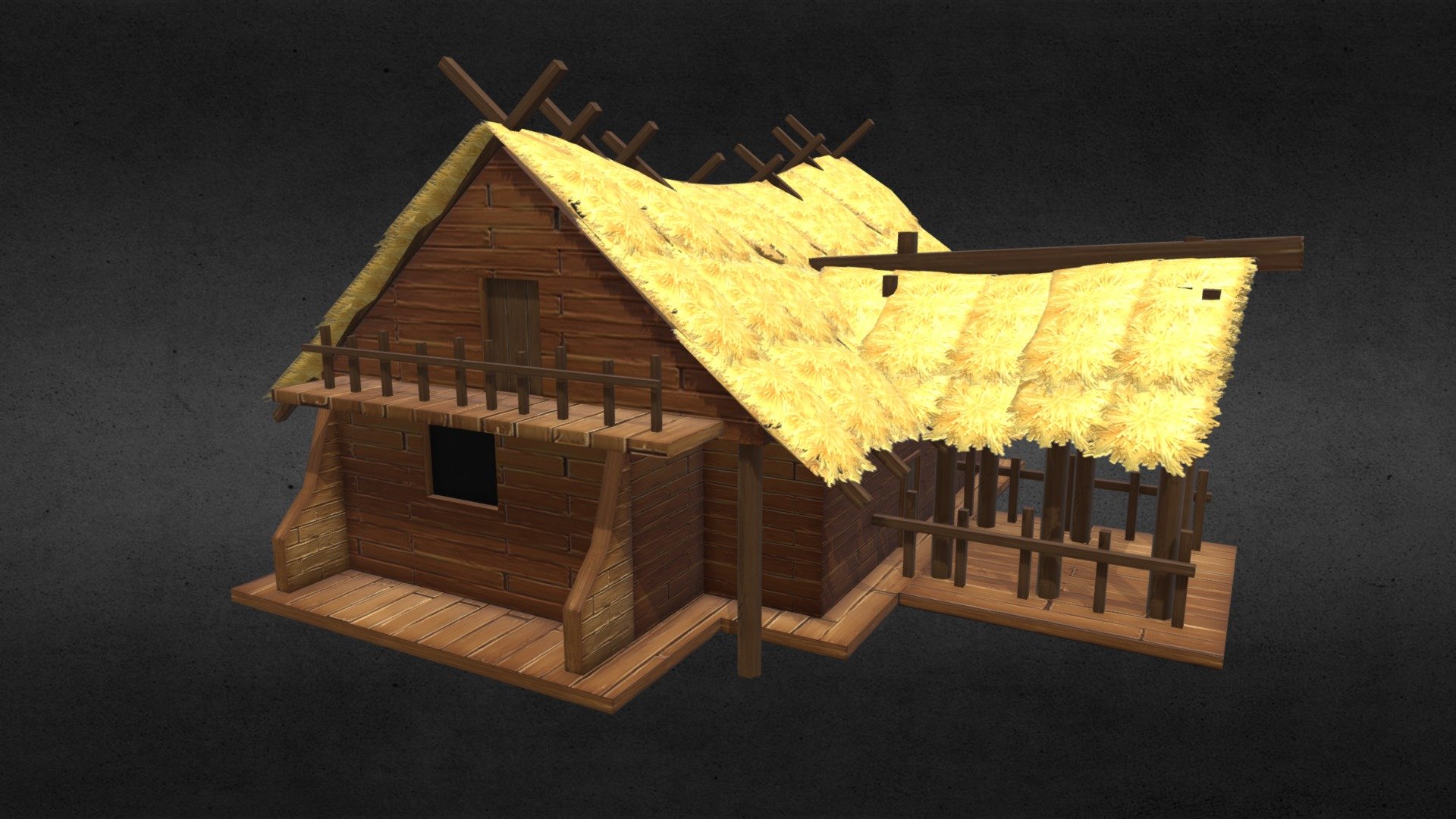

- Strawbale houses are sustainable and eco-friendly dwellings

- Building Envelopes 101

- What Is a Straw Bale House? Definition, Designs, and Examples

- this earth day, designboom revisits the year's top examples of passive architecture

- What type of housing are they?

- All About Straw Bale Homes: Pros and Cons (Is It Efficient?)

Wheat straw, although plentiful, isn’t one of Morrison’s preferred materials. He says the stalks grown on factory farms are too short to make good bales. The layer of plaster on the outside ranges from cement stucco, which can cause moisture issues when it cracks, to clay-based earth plasters, which require reapplication regularly.

Strawbale houses are sustainable and eco-friendly dwellings

The plaster layer that keeps the straw dry and safe from mold or mildew doesn’t last forever. Once it starts to degrade, it must be replaced, meaning maintenance for a straw bale house is required more often than with most other modern homes. Moisture can come from cracks in the plaster, plumbing pipes, damage from flash flooding, or in instances where windowsills or joints have not been properly sealed. For this reason, climates known to be particularly wet or humid may not be ideal for straw bale houses.

Building Envelopes 101

Straw bales are tightly packed and cemented with plaster, making them sturdy structures. You can then place a protective wooden plank over the second to last course of bales and compress the wall with scissor jacks, tightening the ratchet straps as you go. Once the top course of bales is in position, you can remove the straps allowing the soffit to retain them as they spring back up.

What Is a Straw Bale House? Definition, Designs, and Examples

The reduced energy consumption means lower utility bills for homeowners who choose this building method. Strawbale construction makes it possible to build a home that’s both comfortable and economical to operate all year round. Wheat straw and similar materials have been used as effective thermal insulators for centuries, e.g., in straw-thatched roofs and other thatch roofing. Straw bale insulation is still relatively inexpensive compared to other materials with similar insulating properties. High density pre-compressed bales (straw blocks) can bear higher loads than traditional field bales (bales created with baling machines on farms).

How VINES is using straw bales to build new Binghamton office - Pressconnects

How VINES is using straw bales to build new Binghamton office.

Posted: Fri, 04 Aug 2023 07:00:00 GMT [source]

Install prefabricated cassettes to reinforce your wall’s insulation capacity. You can consult a local builder or architect to help develop a suitable design. For this approach, attaining sufficient wall compression remains a challenge since the frame carries the load, so the weight of the building doesn’t help to compress the bales. The commonly used frames are wood and steel, which are considered to have sufficient compressive strength for load bearing.

The design plan should incorporate the size of windows and doors, wall thicknesses, and all the details you need for a sturdy house. The post-and-beam infill is more common because it allows more flexibility and few design restraints. For instance, you can build more stories with longer wall lengths than with load-bearing construction. What must be taken into account is that, as it is a 100% natural material, it is more exposed to rapid decomposition and special care must be taken. In addition, they are flexible and light elements, making them especially useful in seismic terrain. The first step is understanding what local building regulations and codes apply to your area.

Straw bale houses can last a very long time, with some examples being over 100 years old. The key to their longevity is proper construction and maintenance, such as ensuring good drainage and using appropriate materials for plastering. With good care, a straw bale house can provide a comfortable and eco-friendly home for many decades. When it comes to permits and approvals, educating local building authorities about the benefits and safety of straw bale construction can help streamline the process. Additionally, researching and sharing success stories of existing straw bale structures can help alleviate concerns.

Pros and Cons of Straw Bale Construction

Building with straw and hemp could seriously cut emissions - Futurity: Research News

Building with straw and hemp could seriously cut emissions.

Posted: Mon, 25 Mar 2024 07:00:00 GMT [source]

Straw bale homes offer improved indoor air quality due to the natural materials used for construction. The walls, made of straw, allow for better air circulation and moisture control, reducing the risk of mold and allergens typically found in conventional homes. It’s essential to pick the right variety of straw; experts recommend using wheat, triticale (wheat/rye cross), or rye.

In this article, we look at some examples of eco-friendly material and their benefits. Cob houses can be designed to be incredibly energy efficient and comfortable. This article lists some useful cob house design tips that will help you make the most of your budget. It’s worth noting that you can’t apply any old plaster, as is the case with conventional construction. This approach makes the walls good and tight, minimizing air gaps and ensuring you get the best insulation possible from your straw bale wall. However, straw bale construction is re-emerging in the 21st century due to its sustainable and eco-friendly nature.

While some may appreciate the unconventional nature of a straw bale house, it can also create some challenges. Structural engineers may not be familiar with the building approach, making it hard to get solid plans. Inspectors in your area may also not be well educated about straw bale house construction, making it difficult to get passed during the inspection phase.

But what are sustainable materials, and how can you know for sure they are as sustainable as the marketing claims? Furthermore, they are energy efficient and highly insulated, offering conducive living conditions all year round. A good way to ensure the walls are tight and well-compacted is to install a wooden soffit below the height the bales will naturally reach. The first step in the building process is constructing a raised foundation to keep moisture at bay.

While field bales support around 900 kilograms per metre (600 lb/ft) of wall length, high-density bales can bear at least 6,000 kg/m (4,000 lb/ft). No matter which construction method you use, the bales are typically laid flat rather than on edge for extra strength. He says it’s more common because it allows more flexibility and fewer design restraints.

On top of these benefits, straw is often cheaper than other more common building materials like wood or brick. All these features increase the R-value of straw bales by up to and provide far better protection against heat loss than other construction materials. In this article, I will provide an overview of straw bale homes and examine the pros and cons of building one. Straw bale wall systems are 3x more energy-efficient than conventional framing, saving 75% in energy costs!

The high R-values of straw bale insulation make it ideal for climates with harsh winters and hot summers, as they can effectively keep heat out during summer and retain heat in winter. The most significant disadvantage of a straw bale home is its susceptibility to moisture damage if not adequately sealed and insulated. Excess moisture can lead to mold growth, insect infestations, and rot if not appropriately addressed during construction. I’ll also explore its energy efficiency, cost savings, and maintenance requirements. The simulation results show that the annual energy requirement when using straw fibre and olive fibre panels is close to the annual energy requirement for expanded polystyrene panels in both climates. During the cooling season, however, olive fibre and straw fibre insulation panels perform better, with a reduction of approximately 21% in Bilbao and 14% in Bari.

Therefore, they are unwilling to write an insurance policy for such a home. As a result, you’ll need to search around to find a firm that approves insurance for a straw bale home. Contrary to popular belief, straw bale houses are strong and can last more than 100 years. In most cases, the foundation in load-bearing straw bale construction is made from concrete to raise the bales above the ground and prevent them from coming into contact with moisture.

Comments

Post a Comment